CompactLogix 5380 Controllers

The CompactLogix 5380 controllers are a powerful and versatile solution for industrial automation applications. They offer a wide range of features and benefits, including high performance, scalability, and safety. The CompactLogix 5380 controllers are designed for use in a variety of applications, including manufacturing, process control, and machine automation. This manual provides a comprehensive overview of the CompactLogix 5380 controllers, including their features, benefits, and applications. This document will walk you through the installation, configuration, and operation of the CompactLogix 5380 controllers.

Overview

The CompactLogix 5380 controllers are a powerful and versatile solution for industrial automation applications. They offer a wide range of features and benefits, including high performance, scalability, and safety. These controllers are designed for use in a variety of applications, including manufacturing, process control, and machine automation. They are part of the Allen-Bradley Logix 5000 family of controllers, which is a comprehensive suite of programmable automation controllers (PACs) that provide a wide range of functionality and performance. The CompactLogix 5380 controllers are designed to meet the growing demands of smart machines and equipment for manufacturing. They offer a number of key features and benefits that make them ideal for a wide range of applications.

One of the key features of the CompactLogix 5380 controllers is their high performance. They are equipped with a multi-core CPU that provides the processing power needed to handle complex control tasks. The CompactLogix 5380 controllers also offer a wide range of communication options, including EtherNet/IP, ControlNet, and DeviceNet. This allows them to be integrated into a variety of industrial networks. The CompactLogix 5380 controllers also offer a number of built-in safety features, such as integrated motion and safety over EtherNet/IP. This allows them to be used in applications where safety is a critical concern. The CompactLogix 5380 controllers are also very easy to program and configure. They use the Studio 5000 Logix Designer software, which provides a user-friendly interface for developing and deploying applications.

Key Features

The CompactLogix 5380 controllers are equipped with a number of key features that make them a powerful and versatile solution for industrial automation applications. These features include⁚

- High-performance multi-core CPU⁚ The CompactLogix 5380 controllers are equipped with a multi-core CPU that provides the processing power needed to handle complex control tasks. This allows them to handle a wide range of applications, including those that require high-speed processing or complex logic.

- Integrated motion control⁚ The CompactLogix 5380 controllers offer integrated motion control over EtherNet/IP. This allows them to control a variety of motion devices, such as servo motors, stepper motors, and linear actuators. This integrated motion control capability simplifies the design and implementation of motion control applications.

- Flexible I/O options⁚ The CompactLogix 5380 controllers offer a variety of I/O options, including digital, analog, and specialized I/O modules. This allows them to be customized to meet the specific needs of a wide range of applications. The flexible I/O options ensure that the CompactLogix 5380 controllers can be used in a variety of applications, including those that require a high degree of customization.

- Built-in safety features⁚ The CompactLogix 5380 controllers are equipped with a number of built-in safety features, such as integrated motion and safety over EtherNet/IP. This allows them to be used in applications where safety is a critical concern. The built-in safety features ensure that the CompactLogix 5380 controllers can be used in applications where safety is a critical concern.

- Easy to program and configure⁚ The CompactLogix 5380 controllers use the Studio 5000 Logix Designer software, which provides a user-friendly interface for developing and deploying applications. The easy-to-use programming and configuration tools make the CompactLogix 5380 controllers easy to use and manage. This makes it easy for engineers to develop and deploy applications quickly and efficiently.

System Performance and Capacity

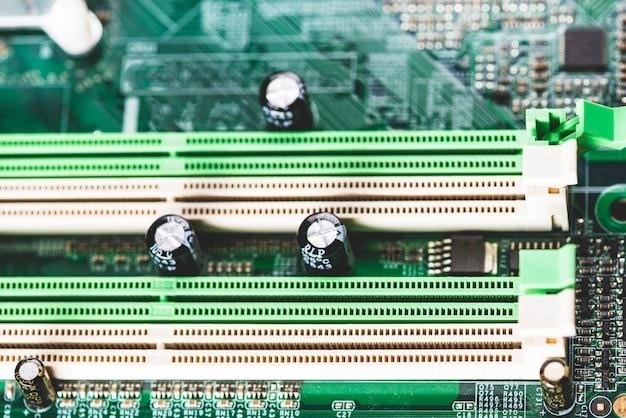

The CompactLogix 5380 controllers are designed to deliver high performance and scalability for demanding industrial automation applications. They offer a range of features and capabilities that enable them to handle complex control tasks, manage large amounts of data, and support a wide range of I/O devices. Some key aspects of their system performance and capacity include⁚

- High-performance CPU⁚ The CompactLogix 5380 controllers are equipped with a powerful multi-core CPU that provides the processing power needed for complex control tasks and data management. This high-performance CPU enables the controllers to handle demanding applications with ease, ensuring smooth and efficient operation even in complex environments.

- Large memory capacity⁚ The CompactLogix 5380 controllers have a large memory capacity, which allows them to store large amounts of data, including programs, configurations, and historical data. This ample memory capacity enables the controllers to handle complex applications that require significant data storage and processing.

- Scalability⁚ The CompactLogix 5380 controllers are highly scalable, meaning they can be easily expanded to accommodate the needs of growing applications. This scalability allows users to start with a basic configuration and then expand it as their needs evolve, without needing to replace the entire system.

- Support for a wide range of I/O devices⁚ The CompactLogix 5380 controllers support a wide range of I/O devices, including digital, analog, and specialized I/O modules. This flexibility allows users to customize their system to meet the specific requirements of their application.

- High-speed communication⁚ The CompactLogix 5380 controllers support high-speed communication protocols, such as EtherNet/IP, which allows for fast and reliable data transfer between the controller and other devices on the network. This high-speed communication ensures that the controllers can handle real-time control tasks and data exchange efficiently.

Networking and Communication

The CompactLogix 5380 controllers excel in networking and communication capabilities, allowing them to seamlessly integrate with other devices and systems within a larger automation infrastructure. This robust connectivity empowers users to build sophisticated control systems and manage data flow effectively. Here’s a breakdown of their key networking and communication features⁚

- EtherNet/IP support⁚ The CompactLogix 5380 controllers are designed with built-in support for EtherNet/IP, a powerful and widely adopted industrial Ethernet protocol. This enables them to communicate with a wide range of devices and systems on the network, including other Logix controllers, I/O modules, drives, and human-machine interfaces (HMIs).

- Multiple Ethernet ports⁚ The CompactLogix 5380 controllers feature multiple Ethernet ports, allowing them to connect to different networks or segments within a network. This provides flexibility for network configuration and allows users to segment their network for enhanced security and performance.

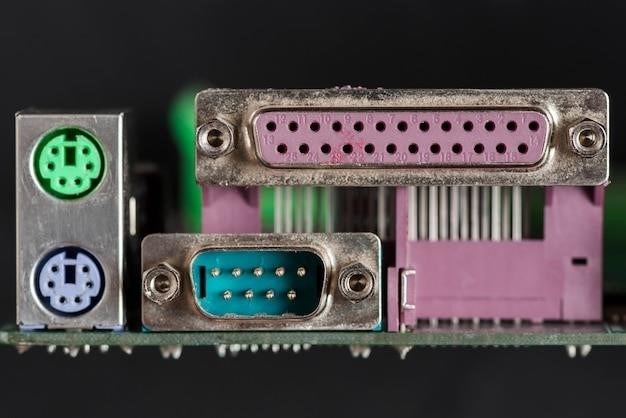

- Integrated communication modules⁚ The controllers can be equipped with integrated communication modules for various protocols, including DeviceNet, ControlNet, and serial communications. This expands their connectivity options and allows them to interact with legacy devices or systems that utilize these protocols;

- Secure communication⁚ The CompactLogix 5380 controllers support secure communication protocols, ensuring data integrity and confidentiality. This is crucial for applications where security is paramount, such as in critical infrastructure or industrial environments where data security is a priority.

- Remote access and management⁚ The controllers’ networking capabilities facilitate remote access and management, allowing users to monitor and control the system from a central location. This simplifies maintenance, troubleshooting, and system updates, enhancing overall operational efficiency.

Safety Features

The CompactLogix 5380 controllers prioritize safety by incorporating a range of features designed to prevent hazards and protect personnel. These features contribute to a safer working environment, minimize risks, and enhance overall system reliability. Here’s a closer look at the safety features included in the CompactLogix 5380 controllers⁚

- Safety-rated controllers⁚ The Compact GuardLogix 5380, a specialized version of the CompactLogix 5380, is specifically designed for safety-critical applications. These controllers meet stringent safety standards and are certified for use in hazardous environments. They include integrated safety functions, such as safety relays and input/output modules, to ensure the safe operation of machines and processes.

- Safety-related I/O modules⁚ The CompactLogix 5380 controllers support safety-related input/output (I/O) modules. These modules are certified for use in safety-critical applications and provide a safe and reliable way to monitor and control safety-related devices and functions. They are designed to meet the requirements of safety standards, such as IEC 61508 and ISO 13849.

- Safety functions⁚ The CompactLogix 5380 controllers support a range of safety functions, including safety relays, safety interlocks, and emergency stop functions. These functions are designed to prevent hazards and protect personnel by detecting and responding to potential safety risks.

- Safety diagnostics⁚ The controllers provide extensive safety diagnostics, which help identify potential safety issues and ensure that safety functions are operating correctly. These diagnostics include self-tests, error messages, and status indicators, allowing users to monitor and manage safety aspects of the system effectively.

- Conformal coating⁚ Compact GuardLogix 5380 controllers are available with a conformal coating, which protects the controller from harsh environments. This coating helps prevent corrosion and damage, ensuring the reliability of the safety functions even in challenging conditions.

Installation and Configuration

Installing and configuring the CompactLogix 5380 controllers is a straightforward process, designed to be user-friendly and efficient. The process involves several key steps, including physical installation, network setup, and software configuration. This section provides a step-by-step guide to help you successfully install and configure your CompactLogix 5380 controller.

- Physical Installation⁚ Begin by mounting the CompactLogix 5380 controller on a DIN rail or other suitable mounting surface. Ensure secure mounting to prevent accidental dislodging. Connect the required I/O modules, power supply, and communication cables to the controller. Refer to the documentation for specific wiring diagrams and connection instructions.

- Network Configuration⁚ Configure the controller’s network settings. This involves assigning IP addresses, subnet masks, and gateway information. The controller can be connected to an Ethernet/IP network, allowing communication with other devices and systems. The setup process may involve using a web browser or a dedicated configuration software tool.

- Software Configuration⁚ Use the Studio 5000 Logix Designer software to configure the controller. This software allows you to define the controller’s program logic, I/O mappings, communication settings, and other parameters. The software provides a graphical interface for creating and managing the controller’s configuration.

- I/O Configuration⁚ Define the input and output points of the controller. This involves specifying the type of I/O modules used and the corresponding physical connections to the controller. The I/O configuration ensures that the controller correctly receives data from sensors and actuators and sends control signals to them.

- Communication Setup⁚ Configure the communication settings for the controller. This involves establishing connections to other devices on the network, such as remote I/O modules, human-machine interfaces (HMIs), and other controllers. The communication configuration allows the controller to exchange data and control signals with other devices.

Programming and Operation

Programming and operating the CompactLogix 5380 controllers involves utilizing the powerful Studio 5000 Logix Designer software. This software allows you to create, edit, and deploy programs for the controller, enabling it to automate your industrial processes. The software provides a comprehensive set of tools and features for developing and managing your automation projects.

- Program Development⁚ Use Studio 5000 Logix Designer to create programs for the controller using a graphical programming language called Ladder Logic (LD). This language allows you to visually represent the control logic of your system, making it easier to understand and modify. The software provides a range of other programming languages, including Function Block Diagram (FBD), Sequential Function Chart (SFC), and Structured Text (ST), to suit different programming styles.

- I/O Mapping⁚ Define how input and output signals are mapped to the controller’s I/O modules. This ensures that the controller correctly receives data from sensors and actuators and sends control signals to them. The software provides tools for configuring I/O mappings, including drag-and-drop functionality for easy configuration.

- Communication Programming⁚ Establish communication links with other devices on the network, such as remote I/O modules, HMIs, and other controllers. The software provides functions for configuring communication protocols, including EtherNet/IP, Modbus TCP, and others. This allows the controller to exchange data and control signals with other devices.

- Online Monitoring⁚ Monitor the controller’s operation in real-time. The software provides tools for viewing data from sensors and actuators, monitoring the execution of program logic, and diagnosing system errors. This allows you to observe the controller’s behavior and troubleshoot any issues that may arise.

- Program Deployment⁚ Deploy the program to the controller. The software allows you to download the program to the controller’s memory, where it will execute and control your industrial processes. The software provides tools for managing program versions and ensuring that the correct program is running on the controller.